1、 What is titanium diboride

Among many compounds, metal borides have better high-temperature performance than metal carbides. For example, diboride (TiB2) cermet products are more suitable for use under high temperature and high corrosion conditions than titanium carbide (TiC) and tungsten carbide (WC) cermet products. The titanium diboride powder is gray (or gray black), ranking sixth among the world's ten known materials with the highest melting point (see Table 1 for the melting point ranking table). The oxidation resistance temperature in the air can reach 1100 ℃. As a new type of ceramic material, it has very excellent physical and chemical properties. In addition to the extremely high melting point, it also has high hardness. Its chemical stability, electrical and thermal conductivity, and mechanical properties at high temperatures are extremely excellent.

Table 1. Materials with the highest melting point in the world

Features of titanium diboride as structural material and functional material:

① Structural materials. The high strength and hardness of titanium boride enable it to be made into tools, wire drawing films, sandblasting nozzles and hard tool materials. At the same time, it can also be used as an additive for composite materials.

② Functional materials. The resistivity of titanium boride is very similar to that of pure iron, so its application in functional materials is very promising. Through the electrical properties of titanium borate, flexible PTC materials can be made.

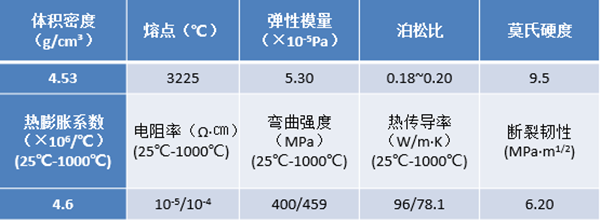

Table 2. Physical Properties of TiB2 Ceramics

2、 Preparation method of titanium diboride raw material

At present, the main methods for preparing titanium diboride raw materials are carbothermal reduction, self propagating high temperature and synthesis, mechanochemical reaction, vapor deposition, ball milling, etc.

① Carbothermal reduction

With titanium and boron oxides as raw materials, carbon black as reducing agent, the titanium diboride powder is reduced in a carbon tube furnace at high temperature for a long time. The purity of the synthesized titanium diboride powder depends on the purity of the raw material powder. This method is a process that is widely used in industrial production. The disadvantage is that the obtained titanium diboride powder particles have large volume and high impurity content.

② SHS

In this process, the raw material mixture to be reacted is generally pressed into a block, and then ignited at one end of the block to ignite the reaction. The huge heat released from the reaction causes the adjacent materials to react, and finally forms a combustion wave spreading at the speed of v. Finally, as the combustion wave advances, the raw material mixture is converted into the final product. Due to the self purification effect of the SHS process, the purity of the product is high, so the powder obtained is easy to further sinter, and the external energy consumption is small. If combined with other special technical means, dense titanium diboride materials can be directly prepared.

③ Mechanical chemical reaction method (MR)

This method is to place the reactant powder in a high-energy ball mill, and the powder changes from deformation to crushing repeatedly under the action of extrusion and shearing of the grinding ball. The severe friction and collision of the ball milling medium cause the mechanical energy to be converted into chemical energy, thus synthesizing the required reactants. Compared with the first two methods to prepare titanium diboride, the mechanochemical reaction method has the advantages of low synthesis temperature, wide sources of raw materials and low cost.

3、 Application direction of titanium diboride

Titanium diboride and its composites can be compounded with other metal and ceramic based polymers to form a series of new materials with commercial application value.

① Titanium diboride can be used as a grain refining and particle strengthening additive, which can be incorporated into aluminum based, copper based titanium aluminum alloys and iron based materials to greatly improve the mechanical and physical and chemical properties of materials. This grain refinement and particle strengthening effect will increase with the increase of purity and fineness of titanium diboride powder.

② Titanium diboride can be compounded with silicon carbide, aluminum nitride, boron nitride, titanium carbide and other non oxide ceramics, or with alumina and other oxide ceramic materials. A large number of experimental studies show that the new composite materials prepared from this have better mechanical strength and fracture resistance toughness, and can be used as one of the high-quality materials for armor protection materials.

③ Titanium diboride particles mixed with high-performance resin can be made into PTC heating ceramics and head type PTC materials, which have the characteristics of safety, power saving, reliability, easy processing and molding. It is a key new and high technology for upgrading household appliances such as electric irons, electric blankets, electric ovens, air conditioners and hot air greenhouses.

④ Titanium diboride has excellent electrical conductivity and excellent resistance to corrosion of molten metals. It can be used to make evaporating vessels, molten metal crucibles, aluminum electrolytic cell cathode, spark plugs and other electrode and contact starting materials.

⑤ Due to the good wettability of titanium diboride and aluminum liquid metal, using titanium diboride as the cathode coating material of aluminum reduction cell can reduce the power consumption of aluminum reduction cell and prolong the life of aluminum reduction cell.

⑥ Titanium diboride can be used to make ceramic cutting tools and moulds. It can be used to manufacture finishing tools, wire drawing dies, extrusion dies, sandblasting nozzles, sealing elements, etc.

Technological innovation

Honesty is the foundation

Contact Number: +86-15698999555 |

Address: NO.6 ,SHENGHUA STREET,TAIHE DISTRICT, JINZHOU CITY, LIAONING PROVINCE, CHINA. |